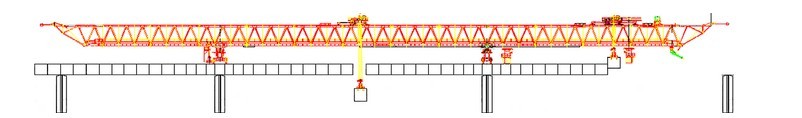

Difference between honeycomb girder and box girder, truss girder

Launching Gantry produced by ZZHZ accesses to national patent with isosceles triangle honeycomb type main girder, it features light self-weight, high stiffness, low deflection and high wind resistance. The main longitudinal girder keeps load-bearing steel plates at two sides of box girder, removes non-load-bearing steel plates at upper and bottom parts, directly welds two sides steel plates together, replaces U-steel at bottom parts, thus the honeycomb girder structure is designed, it keeps the advantages of box girder and overcomes its shortcoming: too heavy.

(1) Compared with box girder, honeycomb girder features low gravity centre, light weight, high safety and strong wind resistance;

(2) Compared with truss girder, the honeycomb girder has a big welding contact area with uniform stress as loading, while the truss girder bears capacity, load-bearing contact point is U-steel welding point which will deformed as loading objects. So honeycomb girder has a lower deflection, higher stiffness. 6 pins connect two main longitudinal girders, short assembly time and uniform load-bearing.

Because main girder of honeycomb girder launching gantry adopts load-bearing steel plate which is USD $100 higher per ton than that of truss girder, the cost of honeycomb girder launching gantry in ZZHZ will be 5% or above higher than that of truss girder launching gantry, based on same configuration and same weight. ZZHZ insists on using honeycomb girder launching gantry because it has three advantages comparing with truss girder:

1. More durable main girder

2. Lower deflection

3. Higher safety