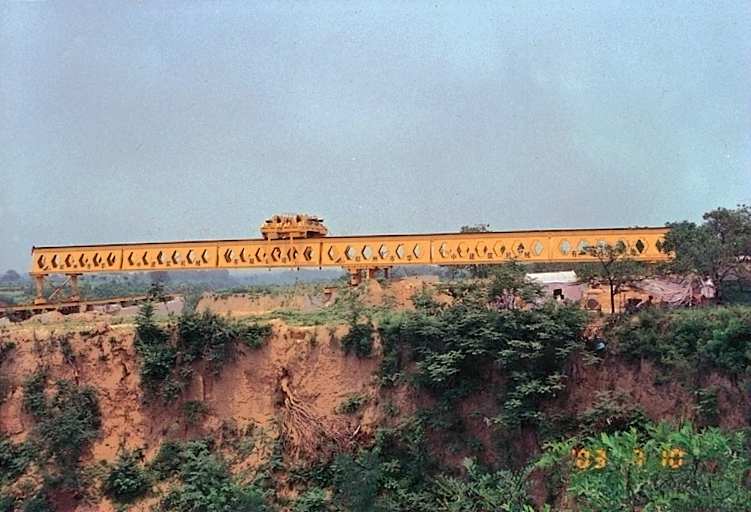

The test run of the launching gantry

1. Check whether all connecting parts are reliable

2. Check whether wire connecting is correct, whether limit switch is flexible and reliable

3. Check whether the hydraulic system has a phenomenon of oil leakage

4. Check whether all mechanical and structure parts will be sot struck.

5. Check the lubrication condition of all turning parts

6. Check whether oil level in the oil tank of pump station meets the demand, if the oil level fails to meet the demand, test run all hydraulic systems

(2) Test run of hydraulic systems should follow the procedures below: connect the power supply, start the oil pump, run under the condition without load. Watch whether oil pump turning direction is correct, monitor whether oil pump runs with noise and other bad conditions, test run without load 5-10 minutes; close relief valve, each oil cylinder stretch out and back 4-5 times under the condition of total travel to eliminate air in the system as far as possible; after finishing test with load and test without load above, check whether all mechanical, institution, hydraulic and electrical parts work well, put it into use if it works normally.

(3) Test run of motor: after finishing connecting wire of electrical system, firstly confirm whether motor turns correctly, remove linkage connection for multi-machine linkage drive system, then confirm the motor turning direction with inching.

Rear support leg driving, rear support leg hydraulic system goes up to make the driving wheels suspend in the air.

Lifting trolley driving and auxiliary support leg driving, firstly confirm the motor turning direction, then install drive chain

After confirming turning direction of all motors, write down work current of each motor as test run of the machinery (current displayed on the frequency converter or clamp ammeter)