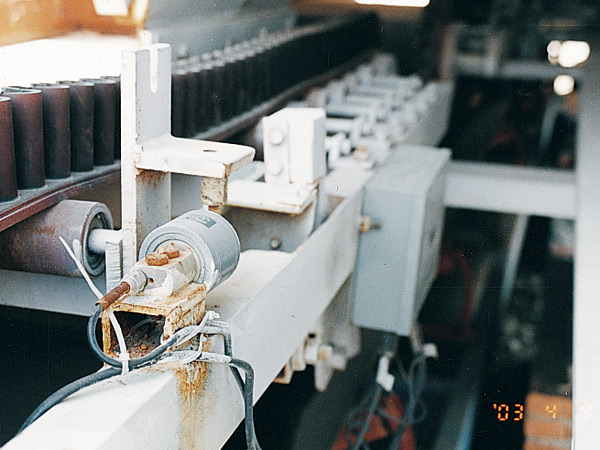

Roadbed Material Mixer

12. The maintenance time and item of Roadbed Material Mixer

● Check the systems frequently to find if there are the phenomena such as: gas leakage, ash leakage, oil leakage and electricity leakage. Once something existed, eliminate it immediately.

● The mixer and discharge hopper need to be cleaned every 4 hours to avoid clotting. Release the standing water in the air-reservoir and filter every shift, eliminate the failures and accidents in the operation process.

● Do a technical maintenance to the machine after it has run 1000 hours (three months). Clean the mechanism parts, add or replace the lubrication oil, grease the bearing. Clean the motor and check the insulation resistance. Proofread and correct the computer, check the humidity-proof of the sensor. Put the filter into 5% of the dilute sulfuric acid to make the clean or replace it.

● After the mixer has operated 2000 hours (half year), not only the maintenance of the above mentioned, but the reducer needs to clean and fill the grease. Clean the bearing, replace the wear parts and fill the grease. Clean the oil cylinder and replace the wear parts.

● Do a complete maintenance and repair every two or three years. Amend or replace the corrosion, wear or deformed pipes and other mechanism parts. Check the motor, coil insulation and clean the bearing, fill the grease. Paint the anti rust for the whole set of machine.

13. The disassembly and site-transferring steps of Roadbed Material Mixer

Dismantling Scheme

Before dismantling the concrete batching plant, we need to make the scheme and safety protection measures. Firstly dismantle the electrical appliance, then the mechanism parts in sequence from top to bottom.

The specific procedures:

Equip with the hoisting equipment with large capacity (lifting height 25m). Prepare the enough space and filed nearby.

● Cut off the water, gas, electricity and other auxiliary facilities. Also close the pipes for electrical appliance, water, additives and air compressor.

● Dismantle the ingredients floor and periphery plate.

● Dismantle the covers of feed-in floor and other structure.

● Dismantle the mechanism parts on the screw conveyor and tape machine. ( Remove the support rods and mechanism parts firstly).

● Dismantle the ingredients floor, mechanism parts and platform.

● Dismantle the upper structure, operating room and its bracing.

● Dismantle the discharge hopper and ladder.

● Dismantle the mixing platform, ladder and support studs.

● Dismantle the aggregate bins and other mechanism parts.

● Dismantle the ash fly bins and other facilities.