Roadbed Material Mixer

7. The quality control in Roadbed Material Mixer manufacturing process

Technology file drawing and project are handed to production department which assorts with related department and quality department to process, manufacture, control, check and accept of product.

The workshops do the following work according to drawing:

● blanking splicing(technology and requirements of blanking splicing)

● assembling welding(welding procedure card, welding technology qualification and welding record)

● mechanical manufacture(mechanical manufacturing card)

● finishing time of manufacture and patrolling card

● Assembly(assembly technology)

● checking descriptive chart(controlling the geometry size and key part).

8. Tracing data and leaving factory data of Roadbed Material Mixer

● The tracing data of product is made up of contract, review file, drawing , calculation book of design, specification, installation project, raw material quality certificate, product quality inspection record, welding inspection report and purchased certificate.

● leaving factory data is made up specification, installation project, certificate and receiving report etc.

9. The installation method and steps of Roadbed Material Mixer

After the foundations has been done and maintained for a period, the structure installation gets started. The whole assembly procedure is from bottom to top, also operating in coordination with the mechanical parts. The exact process is as follows:

● Lift the studs separately, find the centerline and connect with the bolts, then fasten them.

● Assemble the mixing platform to the whole structure on ground. Connect the discharge hopper and mixing platform, the studs and mixing platform, check the positions of every parts to guarantee no mistakes. Then fasten them with the bolts.

● Lift and assemble the ladder and platform (Standard Height 6.00m)

● After the mixing platform is ready, the lifting and assembling of mixer gets started.

● Connect the rods as per the serial number, ensure the dimension tolerance coming to the standard, then fasten them.

● Assemble the weighing platform to the whole structure on ground. Lift and install the weighing platform. Check the dimension tolerance fits in with the standard, then fasten them. When everything is ready, hoist the mechanism parts and electrical appliance to the platform.

● Assemble the feed-in parts on ground separately, then hoist and fasten them to the weighing platform. After that lift and install the roof structure.

● Install the transverse and vertical bracing of periphery structure, then fasten them with the bolts. Also assemble the periphery plate from bottom to top one by one.

● Assemble the operating room structure and set up the electrical appliance on ground ahead of time. Then lift and fix the operating room on the platform.

● Install the support leg of the aggregate bins firstly, then connect them and install the weighing equipments.

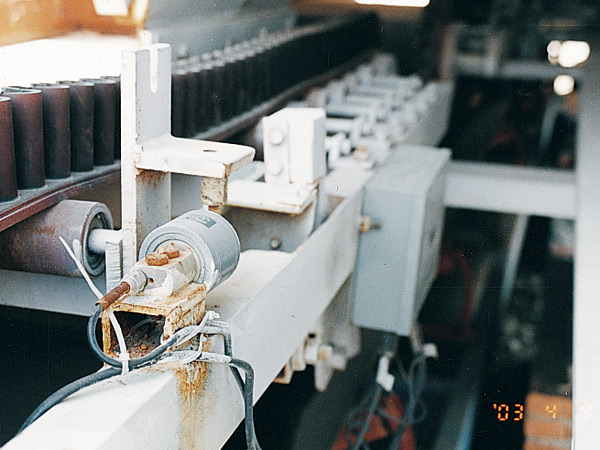

● Install the support rolls, belts, cleaner and other mechanism parts on the conveyor structure ahead of time.

● The installation method is the same for both powder(cement, ash fly) and the above mentioned. The sequence is structure, powder bins, ladder, cleaner and other mechanism parts.

● According to the drawing, assemble the water pipes, additives pipes and air compressor pipes.