Roadbed Material Mixer

4. The design basis of Roadbed Material Mixer

● Design Standard

GB/T10171 <<Concrete Batching Plant>>

GBJ17<<Steel Structure Design Standard>>

● Manufacturing Standard

GB10172 <<Concrete Batching Plant Technical Requirements>>

GB50205 <<Acceptance Standards for Steel Structure Construction>>

SDZ017 <<General Technical Requirements of Machine Processing>>

SDZ018 <<General Technical Requirements for Assembly>>

SDZ018 <<General Technical Requirements for Welding>>

GB/T13384 <<General Technical Requirements for the Machine and Electrical Appliance Package>>

5. Main design requirements of Roadbed Material Mixer

● The concrete batching plant consists of mixer, material-weighing system, material-conveying system, material-storage system, control system and other accessory facilities.

According to the different structure types, the forcible mixer can be divided into main shaft triple motion mixer, single-horizontal-shaft mixer and double-horizontal-shaft mixer. However the double-horizontal-shaft forcible mixer has the best comprehensive performance.

● The material-weighing system is a key part in deciding the concrete quality and production costs. It consists of aggregate-weighing, powder-weighing and liquid-weighing. Generally speaking, we usually adopt the superimposed weighing method when the capacity is less than 20m³/h. It means that a scale for aggregate (sand, stone), a scale for both cement and fly ash, weighing the water and additives separately and mixing them ahead of time. While the capacity is more than 50m³/h, we take the separate weighing method. Any material will be weighed and controlled through electronic scale and computer.

● Aggregate weighing accuracy ≤2%,

● Cement, water, fly ash and additives weighing accuracy≤1%.

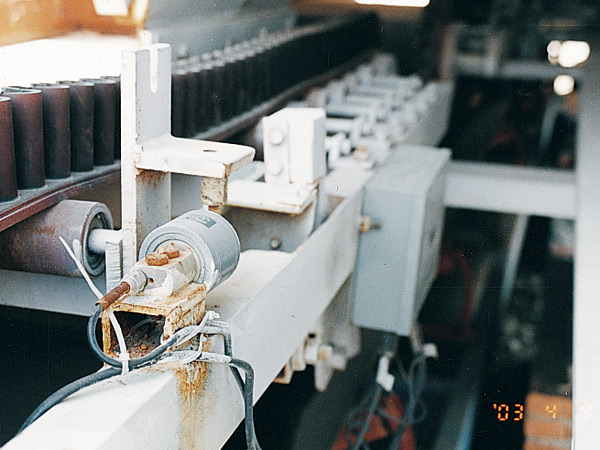

● Material-conveying system consists three parts.

● Aggregate conveyance: Currently we have two conveying methods hopper conveyor and belt conveyor. The hopper conveyor owns the advantages of small land-occupied, simple structure. The belt conveyor owns the advantages of long-distance conveyance, high efficiency and low failure rate. The belt conveyor applies to the batching plant which has the aggregate storage bin, thereby improving the productivity.

● Powder conveyance: The main powder material include cement, fly ash and mining powder which are usually delivered by screw conveyor nowadays. Large-scale batching plant will take the pneumatic or scraper conveyor. The simple structure, low cost and reliability are the advantages of the screw conveyor.

● Liquid conveyance: The water and liquid additives are conveyed by water pump separately.

● The storage method of materials is basically same. The aggregate is stored in an open air (In city large-scale batching plant will adopt the sealed bins or hoppers); the powder is stored in the steel structure bins and the additives are stored in steel structure containers.

● The control system plays the most important role in the whole set of equipment. According to different customers’ requirements and the batching plant scale, the control system equips with different functions and configuration. Under the general circumstance, it will be easier for the small batching plant and the large one will be complex.

6. Main mechanical manufacturing technology of Roadbed Material Mixer

● Firstly the workmanship department evaluates the drawing.

● Draw up the operation instruction then make the judgment.

● According to the drawing, workmanship technology, manufacturing skill and assembly ability to further perfect the dimensions of the machine and meet kinds of requirements. Also do the detection for the mechanical parts.

● Prepare the clamping apparatus according to the drawing.

● Strictly control the quality in the process of production. 5.6,According to kinds of standards, strengthen the management and control in every part and production process.