Roadbed Material Mixer

10. Checking methods after installation of Roadbed Material Mixer

After assembly, the geometry dimension, perpendicularity, levelness and deflection must be checked in the following ways:

● The wheels span deviation: S<10mm

● The main girder deflection: AF=(0.9/1000~1.4/1000)

● The diagonal difference of main girder:(D1-D2)≤5mm

● The side curvature of main girder: AFP≤S/1200

● The trolleys’ gauge difference: Both sides: ±2mm Midpoint: S≤19.5mm

● Adjust the wheels (Parallelism, perpendicularity, apposition)

11. Operating requirements and attention of Roadbed Material Mixer

When the installation is finish, switch on the electrical system to check there is no mistakes. The commissioning needs to be carried with the engineers and electricians. Take the 16 hours non-stop test without load. The specific procedure is as following:

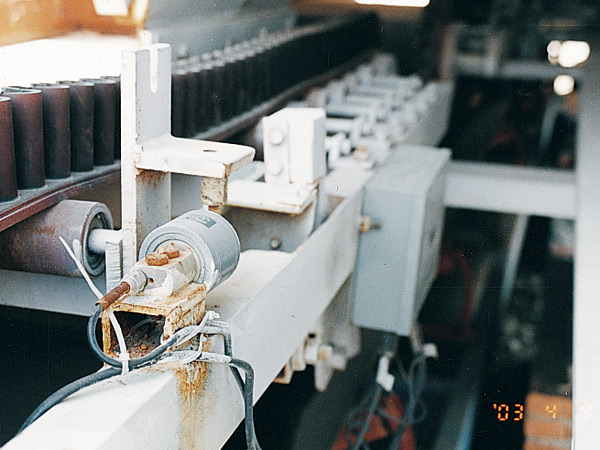

● Keep the belt conveyor running 20 minutes. Ensure that the bearings, motor, reducer and other parts work normally.

● Check the aggregate device has filled the lubrication oil. Adjust the stroke gas cap to make the arc door opening properly.

● Check the ash fly device has filled the lubrication oil. Operate the electromagnetic gas valve, pneumatic butterfly valve to observe its flexibility.

● Operate the screw conveyor to check its sealed condition.

● Adjust the gas-cap stroke of the water, additives equipments to keep the valve hermetically sealed and flexibility.

● Start the mixer to guarantee its operation normally.

● Inspect the pipe system and eliminate the leakage. Check the flow path process operates normally and fill up the oil fogger.

● Check the powder feeding-in condition.

● Inspect the reducer bearing of screw conveyor.

● Check the feeding-in, weighing, mixing, discharging condition.

● Record the period of feeding-in, weighing, mixing and discharging.

● Record the productivity of concrete batching plant

To guarantee the best accuracy, we need to make the record and adjust the set forward quantity of ingredients.