Upstroke Movable Support System

10. Tracing data and leaving factory data of Upstroke Movable Support System

● The tracing data of product is made up of contract, review file, drawing , calculation book of design, specification, installation project, raw material quality certificate, product quality inspection record, welding inspection report and purchased certificate.

● leaving factory data is made up specification, installation project, certificate and receiving report etc.

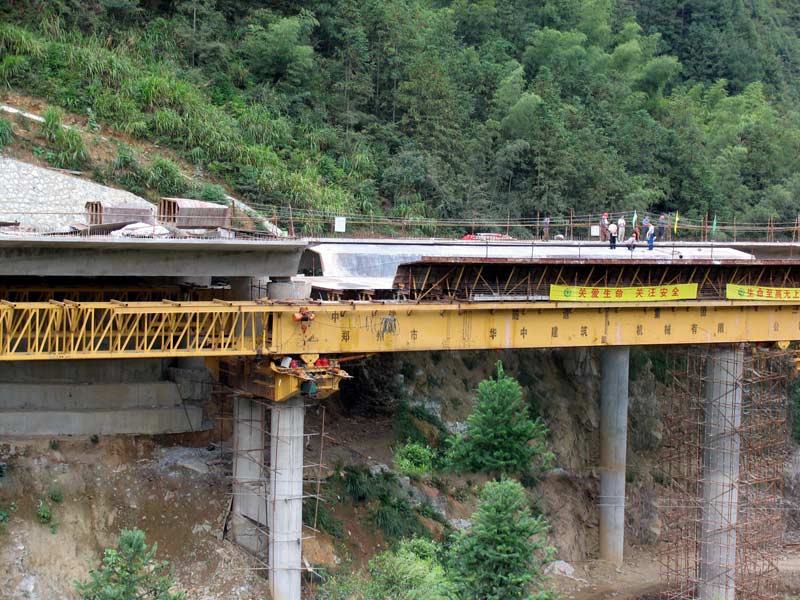

11. The installation method and steps of Upstroke Movable Support System

● Assemble the temporary supporting frame

● Install the front and rear support legs, longitudinal traveling auxiliary support legs

● Assemble the main girder

● Assemble the hydraulic and electrical devices

● Place the whole machine in the proper position

● Install the cantilever beam

● Assemble and hoist the base mould

● Install the side mould frame

● Adjust the base mould plate

● Assemble the side mould plate and poles

● Adjust the side mould plate

● Install wing mould plate

● Assemble the special-shape mould plate and pier top bulk mould

● Carry the pressure and load test

12. Checking methods after installation of Upstroke Movable Support System

Check the dimension, perpendicularity, pre-camber, deflection when the installation is done.

● The overall dimension: 62.5m(L) ×20.6m(W) ×5.6m(H above the bridge)

● The upper deflection of main girder: AF=(0.9/1000-1.4/1000)S

● Adjust the pre-camber to approach the standard of the instructions

● The main girder side curvature: AFP≤S/1200

● Assemble and connect the high-strength bolt according to the standard