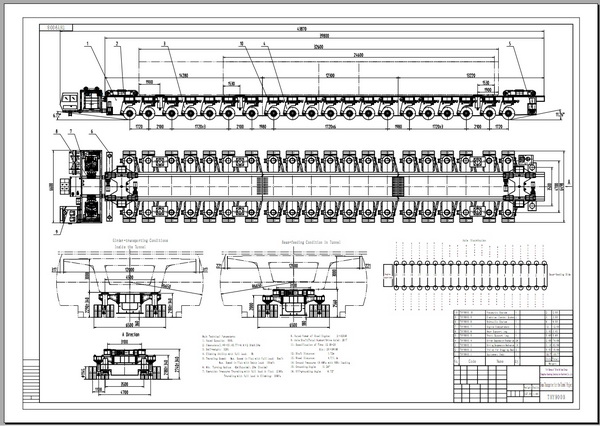

Girder Transporter

6. Main mechanical manufacturing technology of Girder Transporter

● The product mainly chooses Q345C steel; weld joint and outboard main angle weld joint of cover plate and web is of union melt welding, other weld joints adopt CO2 gas shielded welding; welding materials selection: solder wire for union melt welding H10Mn2 matched with HJ350; solder wire for CO2 gas shielded welding ER50-6; welding rod for tack welding in the assembling process E5015. butt-jointed seam has a 100% ultrasonic flaw detection, inspection and acceptance standard GB11345-89, weld joint quality grade 1; penetration weld between cover plate and web, 100% ultrasonic flaw detection will proceed after welding, 1 grade qualified, all T type joints have a X-ray flaw deflection, inspection and acceptance standard: GB3323-87, welding joint quality grade: Level 2.

● It demands derusting by sandblast, derusting grade Sa2.5;casting travelling wheel is demanded a annealing heat treatment; CNC cutting machine is used for steel plate with thickness>10mm; round hole processing for travelling wheel demands to use NC boring machine; press machine must be used to install bearings; special paint for engineering machinery is necessary, outside surface is epoxy zinc rich primer, in the middle epoxy micaceous iron paint, at the end polyurethane paint, overall thickness of paint film ≥125μm, left and right deviation is 5μm.

7. The quality control in Girder Transporter manufacturing process

● Quality control is executed by ZZHZ QC Department and local Quality Inspection Bureau.

8. The drawing of Girder Transporter

Click to download the drawing of Girder Transporter

Click to download the drawing of Girder Transporter